The oil and gas industry is usually divided into three major sectors: upstream (or exploration and production- E&P), midstream and downstream. The upstream sector includes searching for potential underground or underwater crude oil and natural gas fields, drilling exploratory wells, and subsequently drilling and operating the wells that recover and bring the crude oil or raw natural gas to the surface.

1) EOR Solutions

Enhanced oil recovery (abbreviated EOR) is the implementation of various techniques for increasing the amount of crude oil that can be extracted from an oil field. Enhanced oil recovery is also called tertiary recovery (as opposed to primary and secondary recovery)

Enhanced Oil Recovery (EOR) or “Tertiary Oil Recovery”, as the name suggests, is the third and final stage implemented in recovering all the crude oil possible from an oil reservoir.

There are a number of techniques currently used for Enhanced Oil Recovery, each of which has varying implications on cost, efficiency and safety. Of all the techniques, Surfactant Water Injection EOR is receiving more attention in recent years, primarily due to its increasing cost effectiveness against the backdrop of rising oil prices.

Types of Enhanced Oil Recovery

Oil production can be broken down into three phases: Primary, Secondary and Tertiary (or Enhanced Oil Recovery). Each phase requires an increasing amount of technology and energy to recover the oil. This, in turn, increases the cost of well production. With increasing global demand and oil prices the costs associated with more expensive techniques are fast becoming less of an issue.

Primary & Secondary Recovery

Primary recovery relies on naturally occurring pressure within the oil reservoir to drive oil to the surface. This method typically leaves around 85%-95% of the oil behind.

Secondary oil recovery introduces external energy to the oil reservoir when naturally occurring pressure is no longer sufficient to bring oil to the surface. It does this by injecting water (water-flooding) or by pumping compressed gasses into the reservoir. The success of secondary oil recovery is limited by the characteristics of the oil reservoir itself and can become ineffective early on. Secondary oil recovery leaves anywhere between 50% – 80% of the oil unrecovered.

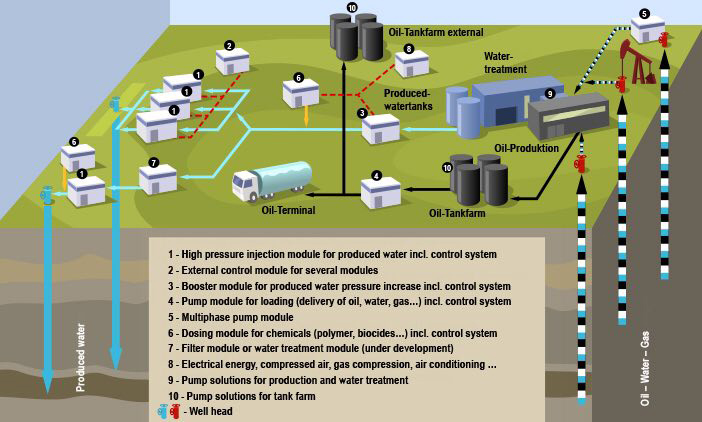

PMC with its partner Sonnek Engineering is active in WATER INJECTION – EOR with the best technology for IRAN oil fields, Not Only WATER INJECTION-EOR SOLUTIONS for increasing oil production is our goal; But Also, WATER DISPOSAL SOLUTIONS is one of our main targets in IRAN Market.

Having a strong/Flexible/Modular water injection packages besides the comprehensive water treatment technology and reputable Austrian reservoir engineering company besides a well-known consultancy company, make us a trustable partner for our clients as EOR SOLUTION Provider in a firm chain from A to Z, CASE STUDY SCHEMATIC.

Looking to our international track in both EOR and Water Disposal ensure clients that an experienced partner with global high technology with local manufacturing makes a perfect selection to cooperate in projects.